Understanding AC Foaming Agents: Key Insights for the Chemical Industry

Release time: 2025-07-14

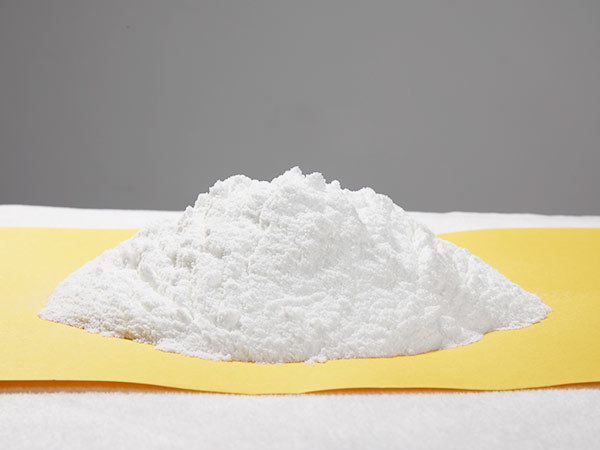

AC foaming agents are critical components in various applications across the chemical industry, particularly in the manufacture of foamed products. These agents, known for their ability to create stable foam structures, play a pivotal role in enhancing product performance and efficiency. Understanding how these agents work, their types, and their various applications can significantly benefit professionals in the field.

AC foaming agents generally operate by reducing the surface tension of liquids, allowing for the formation of bubbles and foam. They can be classified into two categories: chemical foaming agents and physical foaming agents. Chemical foaming agents release gas upon decomposition, while physical foaming agents rely on the physical properties of materials, such as temperature or pressure, to create foam.

One of the primary uses of AC foaming agents is in the production of lightweight materials. In the construction industry, for example, these agents are used to create lightweight concrete and foam insulation products, leading to improved energy efficiency and lower transportation costs. Additionally, the incorporation of AC foaming agents in consumer goods, such as cosmetic products and detergents, enhances texture and application, making them more appealing to consumers.

Innovation in AC foaming agents has been driven by the demand for more sustainable and environmentally friendly solutions. Many manufacturers are now focusing on bio-based foaming agents that minimize environmental impact while maintaining performance. These sustainable options not only meet regulatory requirements but also resonate with a growing consumer preference for green products.

Another significant advancement is the improvement in the stability and durability of foamed products. Enhanced formulations of AC foaming agents can provide better resistance to collapse, ensuring that products maintain their intended performance over time. This stability is particularly crucial in applications where longevity and reliability are paramount, such as in the automotive and aerospace industries.

In conclusion, AC foaming agents play a vital role in the chemical industry, influencing various sectors through their ability to generate stable and effective foam. With ongoing advancements in formulations and a shift towards sustainability, professionals in the field must stay informed about the latest trends and technologies. By leveraging the unique properties of AC foaming agents, businesses can enhance product performance, reduce costs, and respond more effectively to market demands. Understanding these agents is essential for anyone involved in the development and application of foamed materials within the chemical sector.

AC foaming agents generally operate by reducing the surface tension of liquids, allowing for the formation of bubbles and foam. They can be classified into two categories: chemical foaming agents and physical foaming agents. Chemical foaming agents release gas upon decomposition, while physical foaming agents rely on the physical properties of materials, such as temperature or pressure, to create foam.

One of the primary uses of AC foaming agents is in the production of lightweight materials. In the construction industry, for example, these agents are used to create lightweight concrete and foam insulation products, leading to improved energy efficiency and lower transportation costs. Additionally, the incorporation of AC foaming agents in consumer goods, such as cosmetic products and detergents, enhances texture and application, making them more appealing to consumers.

Innovation in AC foaming agents has been driven by the demand for more sustainable and environmentally friendly solutions. Many manufacturers are now focusing on bio-based foaming agents that minimize environmental impact while maintaining performance. These sustainable options not only meet regulatory requirements but also resonate with a growing consumer preference for green products.

Another significant advancement is the improvement in the stability and durability of foamed products. Enhanced formulations of AC foaming agents can provide better resistance to collapse, ensuring that products maintain their intended performance over time. This stability is particularly crucial in applications where longevity and reliability are paramount, such as in the automotive and aerospace industries.

In conclusion, AC foaming agents play a vital role in the chemical industry, influencing various sectors through their ability to generate stable and effective foam. With ongoing advancements in formulations and a shift towards sustainability, professionals in the field must stay informed about the latest trends and technologies. By leveraging the unique properties of AC foaming agents, businesses can enhance product performance, reduce costs, and respond more effectively to market demands. Understanding these agents is essential for anyone involved in the development and application of foamed materials within the chemical sector.

sales@feihengchem.com

sales@feihengchem.com

+8615665855919

+8615665855919 中文

中文 English

English España

España