Unlocking the Benefits of PVC Processing Aids in Chemical Applications

Release time: 2025-07-15

Unlocking the Benefits of PVC Processing Aids in Chemical Applications

Table of Contents

1. Introduction to PVC Processing Aids

2. Understanding the Role of PVC in Chemical Applications

2.1 What is PVC?

2.2 The Significance of PVC in Modern Industries

3. Types of PVC Processing Aids

3.1 Lubricants

3.2 Impact Modifiers

3.3 Processing Stabilizers

4. Key Benefits of Using PVC Processing Aids

4.1 Enhanced Processability and Efficiency

4.2 Improved Mechanical Properties

4.3 Cost-Effectiveness

5. Applications of PVC Processing Aids in Various Industries

5.1 Construction Industry

5.2 Automotive Sector

5.3 Electrical and Electronics

5.3.1 Insulation and Cables

5.4 Consumer Goods

6. How to Choose the Right PVC Processing Aid

6.1 Assessing Application Requirements

6.2 Evaluating Compatibility and Performance

7. Best Practices for Using PVC Processing Aids

7.1 Proper Dosage and Mixing Techniques

7.2 Monitoring and Quality Control

8. Frequently Asked Questions (FAQs)

9. Conclusion

1. Introduction to PVC Processing Aids

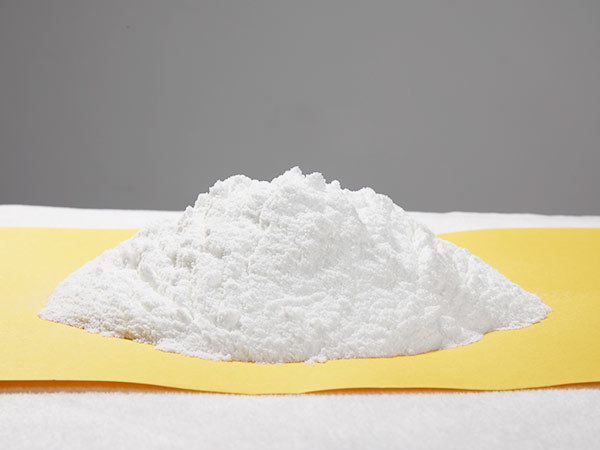

PVC (Polyvinyl Chloride) processing aids play a crucial role in enhancing the performance and efficiency of PVC products in various chemical applications. These additives are designed to facilitate the processing of PVC, improving its flow characteristics and mechanical properties. In this article, we will explore the transformative benefits of PVC processing aids, their types, applications, and best practices for use.

2. Understanding the Role of PVC in Chemical Applications

2.1 What is PVC?

PVC is one of the most widely used synthetic polymers, known for its versatility and durability. It is utilized in a myriad of applications ranging from construction materials to consumer goods.

2.2 The Significance of PVC in Modern Industries

With its excellent chemical resistance, mechanical strength, and low cost, PVC has become an indispensable material in various industries. However, processing PVC can be challenging due to its high viscosity and tendency to degrade under heat. This is where PVC processing aids come into play.

3. Types of PVC Processing Aids

There are several types of PVC processing aids, each serving a unique function to optimize the properties of PVC.

3.1 Lubricants

Lubricants reduce friction during processing, allowing for smoother flow and improved material handling. They enhance the melt flow of PVC, making it easier to mold and shape.

3.2 Impact Modifiers

These additives improve the toughness and impact resistance of PVC products. By incorporating impact modifiers, manufacturers can produce materials that withstand mechanical stress without breaking.

3.3 Processing Stabilizers

Stabilizers protect PVC from thermal degradation during processing. They ensure that the polymer maintains its integrity and desired properties throughout the heating process.

4. Key Benefits of Using PVC Processing Aids

Utilizing PVC processing aids brings numerous advantages to manufacturers and end-users.

4.1 Enhanced Processability and Efficiency

With the right processing aids, the flow properties of PVC are significantly improved. This leads to shorter processing times, reduced energy consumption, and lower production costs.

4.2 Improved Mechanical Properties

PVC processing aids can enhance the mechanical properties of the final product, including tensile strength, flexibility, and impact resistance. This results in higher quality products that meet industry standards.

4.3 Cost-Effectiveness

By improving processing efficiency and reducing material waste, PVC processing aids can lead to significant cost savings for manufacturers. These savings can be passed on to consumers, making products more affordable.

5. Applications of PVC Processing Aids in Various Industries

PVC processing aids are utilized across multiple sectors, demonstrating their versatility and importance.

5.1 Construction Industry

In construction, PVC is used for pipes, fittings, and flooring. Processing aids improve the workability of these materials, ensuring they can be easily molded into various shapes.

5.2 Automotive Sector

PVC is employed in automotive interiors, dashboards, and trim. Processing aids enhance the durability and aesthetic appeal, contributing to higher quality vehicles.

5.3 Electrical and Electronics

5.3.1 Insulation and Cables

PVC is a popular choice for insulation in electrical cables. Processing aids ensure that the material remains flexible and resistant to environmental factors, enhancing performance in electrical applications.

5.4 Consumer Goods

From toys to household items, PVC is prevalent in consumer goods. Processing aids allow manufacturers to create products that are both functional and visually appealing.

6. How to Choose the Right PVC Processing Aid

Selecting the appropriate processing aid is critical for achieving optimal results in PVC applications.

6.1 Assessing Application Requirements

Understanding the specific needs of the application, such as temperature tolerance and mechanical stress, is essential in choosing a processing aid.

6.2 Evaluating Compatibility and Performance

Conducting compatibility tests between the PVC resin and processing aids can prevent issues during production. Performance evaluations ensure that the chosen aids meet desired properties.

7. Best Practices for Using PVC Processing Aids

Implementing best practices can maximize the benefits of PVC processing aids.

7.1 Proper Dosage and Mixing Techniques

Following manufacturer recommendations for dosage ensures that processing aids are used effectively. Proper mixing techniques are also crucial for achieving uniform distribution.

7.2 Monitoring and Quality Control

Regular monitoring of the production process and implementing quality control measures will help maintain the integrity of the PVC products.

8. Frequently Asked Questions (FAQs)

FAQ 1: What are PVC processing aids, and why are they important?

PVC processing aids are additives that improve the processing and performance of PVC materials in various applications. They enhance flow characteristics, mechanical properties, and overall product quality.

FAQ 2: How do processing aids affect the cost of PVC products?

While there is an initial cost associated with processing aids, they often lead to reduced production costs and material waste, making PVC products more cost-effective in the long run.

FAQ 3: Can PVC processing aids improve the recyclability of PVC products?

Certain processing aids can enhance the recyclability of PVC products by improving their thermal stability and mechanical properties, making them more suitable for recycling processes.

FAQ 4: Are there any environmental concerns associated with PVC processing aids?

Like many additives, some PVC processing aids may pose environmental risks. However, advancements in additive technology have led to the development of more environmentally friendly options.

FAQ 5: How can I test the performance of PVC processing aids in my applications?

Conducting laboratory tests to assess the compatibility, mechanical properties, and processing efficiency of PVC processing aids will provide valuable insights into their performance in specific applications.

9. Conclusion

In summary, PVC processing aids are essential components that unlock the full potential of PVC in various chemical applications. By understanding their types, benefits, and best practices, manufacturers can optimize their processes, enhance product quality, and drive down costs. As industries continue to evolve, the role of PVC processing aids will become increasingly important, paving the way for innovation and improved performance across sectors. Embracing these additives is a strategic move for businesses aiming to stay competitive in the ever-changing landscape of chemical applications.

sales@feihengchem.com

sales@feihengchem.com

+8615665855919

+8615665855919 中文

中文 English

English España

España